We care about the environment

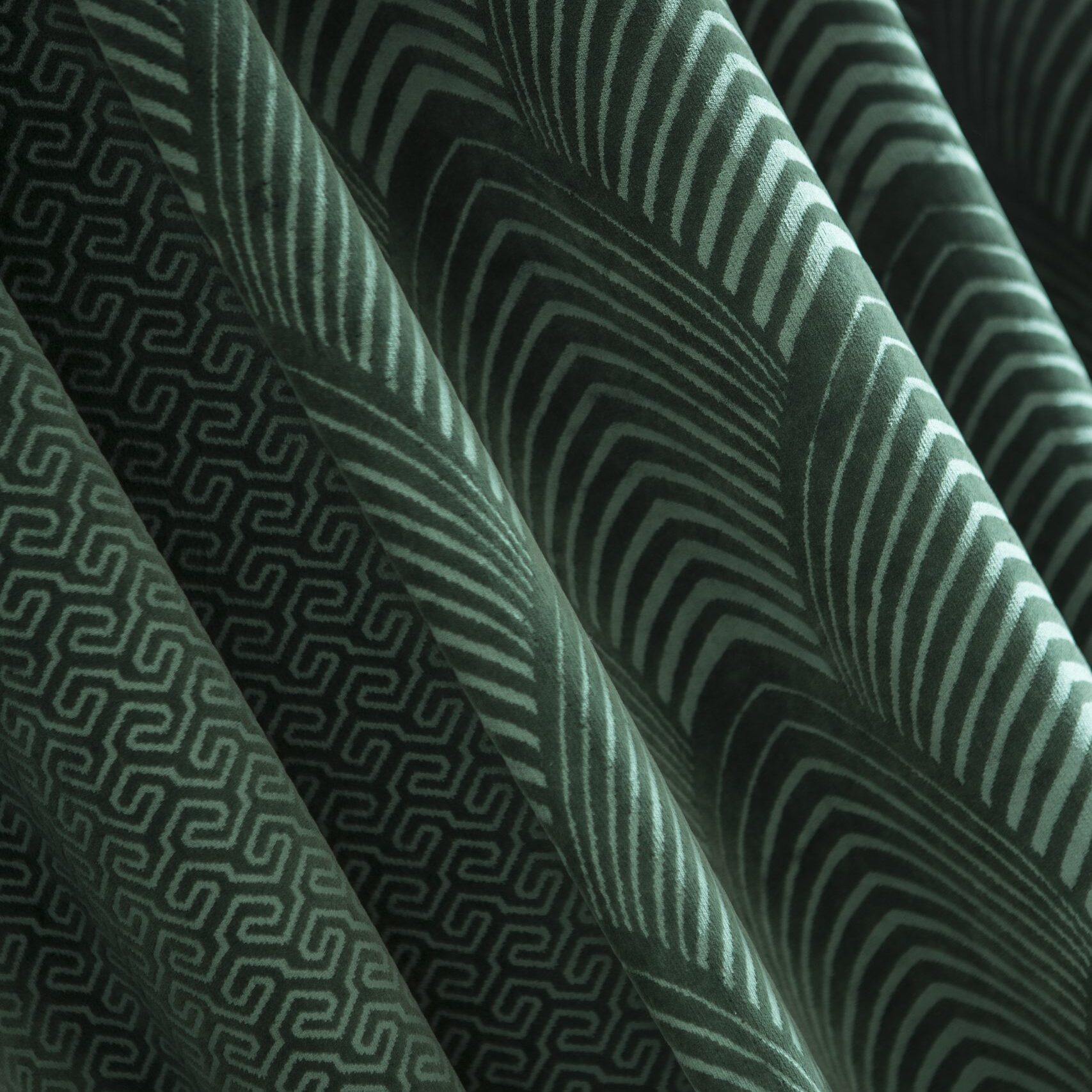

GREEN RAYMAKERS

At Raymakers we strive to reduce the environmental impact of our production and work processes on a continuous basis. Our goal is to develop the best in functional design whilst ensuring a profitable operation, fashionable products and a minimum impact on the environment. Investments in new technology are assessed on their improvement on the quality and efficiency of our production, health and safety of our people and a reduced impact on the environment.

From summer 2021 all our cotton yarns have been at least 20% recycled and for virgin cotton we have only been using BCI yarn (www.bettercotton.org).

You can read all about it in our brochure.

At Raymakers we strive to reduce the environmental impact of our production and work processes on a continuous basis. Our goal is to develop the best in functional design whilst ensuring a profitable operation, fashionable products and a minimum impact on the environment. Investments in new technology are assessed on their improvement on the quality and efficiency of our production, health and safety of our people and a reduced impact on the environment.

The next step to reduce our environmental impact

At Raymakers we strive to reduce the environmental impact of our production and work processes on a continuous basis. For almost 250 years we have been a considerate company in our society and have a long tradition of taking responsibility for our people, for our local society, for the environment and in the markets where we are active.

As the market leader in plain cotton velvets, we have pioneered already in 2006 the use of organic cotton and more recently the use of BCI cotton (Better Cotton Initiative) for a curtain and an upholstery cotton velvet. All chemicals that we are using in our production are fully REACH compliant and the water we use to dye our velvets is returned to surface water after cleaning. Our products carry the OEKOTEX® Standard 100 label.

Now we are taking a next step in reducing our environmental impact by replacing the use of conventional virgin cotton with BCI cotton, for all our cotton velvets. Using BCI cotton means a considerable reduction in the use of pesticides, fertilizer and water, when growing the cotton. (www.bettercotton.org) Moreover, we will include a content of at least 20% of pre-consumer recycled fibers in all our cotton velvets. The look and feel of the velvets and their technical specifications will not be affected by this important change.

All new productions of our cotton velvets will be manufactured with the new “Green” content, which will be gradually phased into our stocks and those of our customers. To offer our customers and third parties transparency about using these sustainable raw materials, we will work and administer it according to the guidelines of ISO 14021. All our cotton yarn purchases with a content of recycled fibers, will carry the GRS-label. Triennial we will be audited on our use of recycled fibers by OEKOTEX®. Annually we will publish our Green Report on www.raymakers.com, starting by the end of this year.

This is an important step to make our products and processes more sustainable. Next steps, also for other parts of our product offer, will follow. We believe that post-COVID19 the consciousness for the well-being of our planet becomes ever more important and we wholeheartedly adapt our products and processes to that.

You can read all about it in our brochure.

Are you interested in our Green Fabrics?

Take your step to reduce the environmental impact and click here